How We Bring Our Tools to Life

At Nova, every product starts with a simple question: how can we make this safer and easier for you? Whether it’s a knife or another safety tool, we focus on creating designs that feel good to use and give you peace of mind.

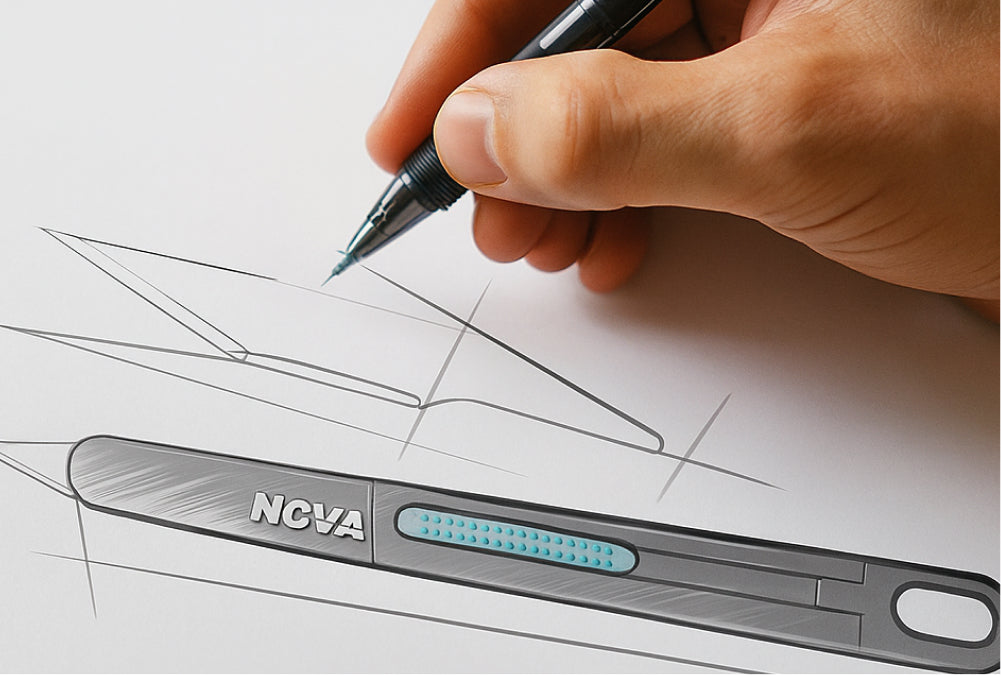

Ideas & Design

At Nova, every product starts with a simple question: how can we make this safer and easier for you? Whether it’s a knife or another safety tool, we focus on creating designs that feel good to use and give you peace of mind.

"I really love shopping at Nova. The products feel strong and well-made, and I can tell they’ll last a long time. The knife I got is super safe to use and the wallet is so comfortable to carry. Everything looks cool too. I feel like I can trust this brand, and I’d definitely buy from them again."

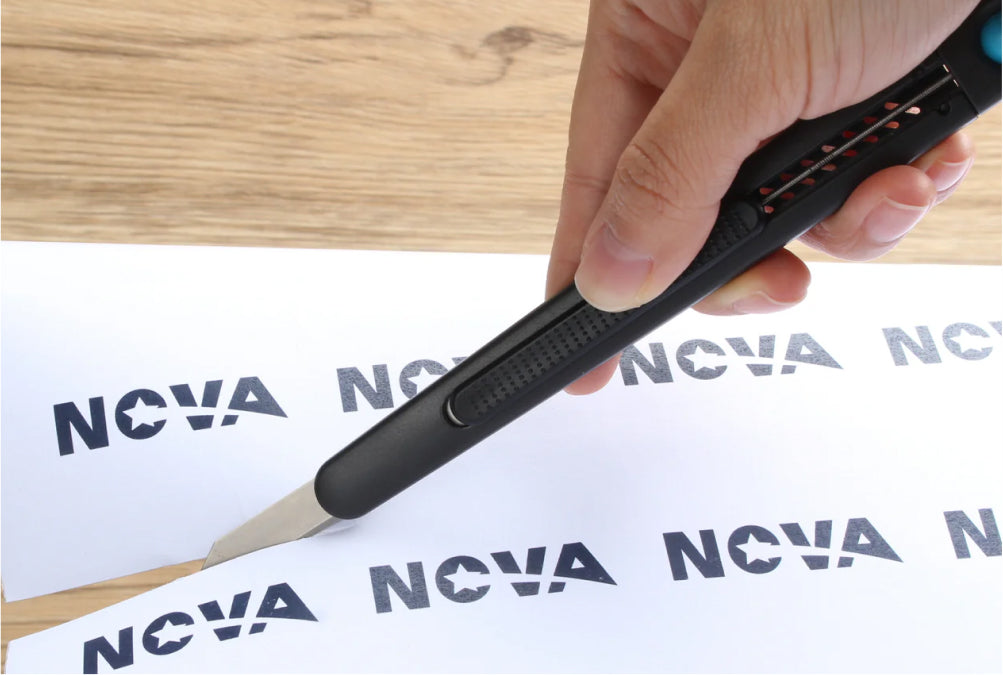

Prototyping & Testing

Then comes the trial-and-error stage. Using 3D printing and other methods, we create prototypes so we can see what works and what doesn’t. This lets us improve fast, test safely, and make sure the final design is something you can truly count on.

Production with Care

Once we know a tool meets our standards, it’s time to bring it into the real world. We choose strong, reliable materials and stick to the highest safety practices. Every tool we produce is built to be durable, safe, and ready for whatever job you need it for.

BEST SELLERS

Smart. Safe. Reliable.

Our best sellers are designed with safety and comfort in mind, making everyday living simpler, sharper, and more reliable.

@novasafetytools

FOLLOW US ON IG

Box Cutter

Box Cutter

Craft Knife

Craft Knife

Lifestyle

Lifestyle

EDC

EDC

Scraper

Scraper

Blades

Blades