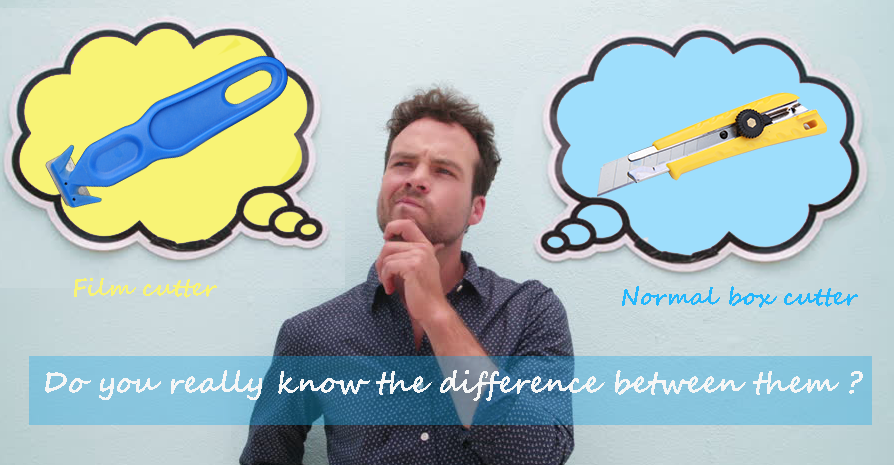

You may know the normal box cutter very well because it appeared everywhere in your life, but about the film cutter, how many people know the advantage of it? Please keep reading this article,I assure that you will know all you need to know about a film cutter.

What Is A Film Cutter?

Film cutter (also known as Concealed box cutter) is a safety tool to help people cut things without worry to hurt themselves because of the concealed blade. It is perfectly designed to help you cut the shrink wrap with much ease. With the film cutter, you can start the cut on your plastic bands, ribbon and twin as well as on strings.

You will enjoy the following significant features by acquiring this film cutter today:

Scraper head design allows usage as a scraper

Concealed blade provides maximum safety

Comfortable ergonomic grip due to the use of high impact plastic with a thumb rest

It has nicely angled cutting blade glides via stretch wraps

Comparison between Film Cutter and Normal Cutter

Film Cutter is Safer: Role number one. Using a film cutter does not expose one to the dangers of sustaining injuries since its cutting edge is not exposed.

Film Cutter is Convenient for Cutting the Wrapping Film: Film cutter is more convenient than the normal box cutter for cutting wrapping film on pallets.

Film Cutter Would Not Damage The Products Under The Carton Box: A film cutter's blade is concealed making it not possible to damage the products underneath the box while cutting.

Both Film Cutter and Normal Cutter Can Be Used for Box Opening: Opening a box is not an “exclusive” feature of a box cutter. A film cutter will conveniently do you the task too.

Film Cutter Can Be Used as Scraper: While normal cutter cannot be used as a scrapper, a film cutter can double task by acting as your scraper to smoothen the cutting edge.

Ambidextrous: Film cutter could be used left hand and right hand. A film cutter, unlike some box cutters, is not limited to one side of cutting. It has a double cutting edge, hence can cut both right and left-hand side.

Film cutter is handy & lightweight: film cutter is made of lighter materials as compared to the normal box cutter. Therefore, it reduces fatigue while using it.

Usage

The film cutter is utilized in cutting a variety of materials. The safety knife can cut up to ten different materials regardless of their thickness.

The following are the common materials handled by a film cutter

Boxes: A film cutter can find tiny tabs to pull them apart. It is also capable of cutting through the box by tearing apart the rigid and stiff part using its sharp blades.

Tape: Film cutter is specifically and professionally designed to cut through plastic tapes, twine, and strings from various packaging and pallets.

Standard and Thicker Corrugated Materials: Film cutter cuts thicker and standard materials of almost all types.

Straps and Banding: The film cutter can quickly get you the straps off your boxes. The tiny tab it has makes it an ideal tool for pulling apart the tabs. Remember to cut at a 45-degree angle to the edge of straps. It will make the cut much easier.

Plastics: The film cutter is used to cut plastics since it has a sharp blade that can cut through the rigid plastic. Nevertheless, the user should understand that plastics may be too hard to the extent of making it risky to cut. The cutter can easily slip and cut the user. It requires much keenness.

Wrapping film: The film cutter comes with a film splitters that can comfortably nestle the plastic band within its head to the knife. Therefore, it allows the blade to snap the plastic film into half. In this manner, it does not expose the user to injuries, and it is swift and easy.

Mailing Box Label: This safety tool also enjoys the existence of sharp and curved edges that make it possible for it to remove the mailing and box labels in industries.

Packing Slip Envelope: Film cutter is an embedded blade hook knife that has a sharp end to unveil the packaging slip with a lot more ease. It cuts through the strings to open packaging boxes without a struggle.

Tips On How To Use A Film Cutter

Cut Banding at a Downward Angle of 45 Degrees: Always ensure that the film cutter is at 45 degrees when cutting material of 2 to 6-millimeter thickness. However, you can always use this angle for other purposes since it is a universal cutting position to reduce injuries.

Start the Stretch Wrap Cut from the Bottom and Pull up towards the Top of the Pallet: This will help in reducing the amount of damage to the stretch wrap during cutting. It will also limit the chances of wastage while wrapping the products on pallets.

Start cut at the Corner Opening of the Box: This will help to make diagonal cuts that can act as joineries while joining the cut parts. The corner cut also makes it easy for one to maintain the angle of cut by reducing errors.

Angle Handles Slightly to Improve the Smoothness of the Cut: When cutting using a film cutter, do not make the handle too straight. Angle it a bit to increase the accuracy and smoothness of your wound. Cutting at an angle also makes it easier for you when making joint cuts.

Conclusion

Film cutter is the necessary tool, especially for the people who need to open the box, cut the film for long working time; it will make you high efficiency and safety at working time. You can also use it in various functions such as plastic straps cutting and wrapping of the box in the warehouse. However, the film cutter is limited in one aspect. It cannot cut objects directly from the surface. It also finds it hard to cut extremely hard materials.

Box Cutter

Box Cutter

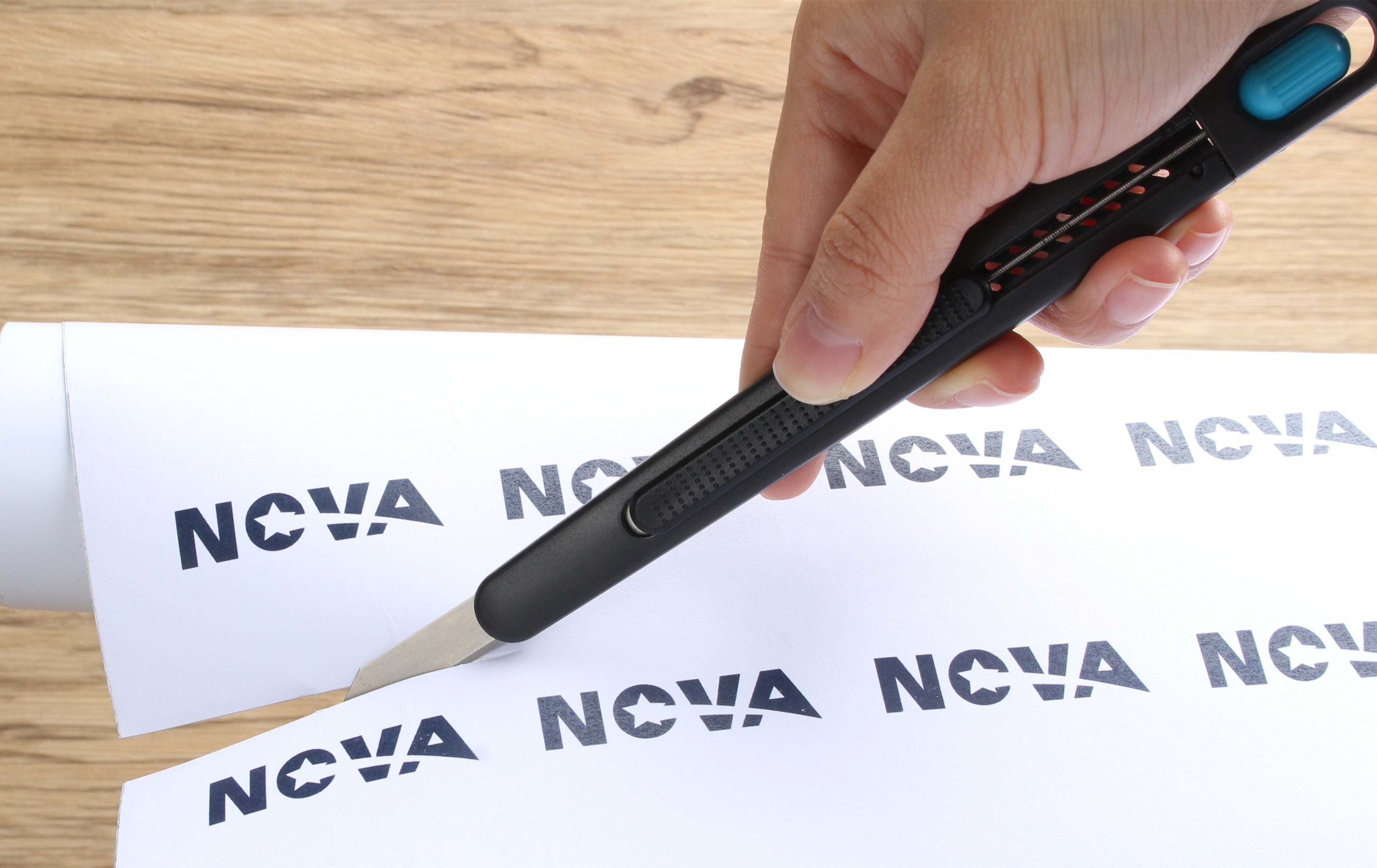

Craft Knife

Craft Knife

Lifestyle

Lifestyle

EDC

EDC

Scraper

Scraper

Blades

Blades